The warehouse management system has innumerable benefits and is the need of the hour. Businesses are striving hard to gain a competitive advantage with the use of software solutions and applications that help ease complex processes. One such solution is Fulfillor – A full-fledged Warehouse Management Solution that serves innumerable benefits to businesses of every industry and sector. Similarly, Fulfillor’s WMS has also helped boost the supply chain efficiency of businesses.

So, if you are into the supply chain industry, look no further, for this blog will help! Here we will help you explore WMS with its features and benefits in the SCM.

WMS – Overview, Features, and Benefits

WMS, short for Warehouse Management System is a software solution developed to ease the workflows and other warehousing activities. Right from picking, packing, and shipping, to tracking, it helps make every activity seamless with top-notch features and innumerable benefits.

A WMS comprises key features like inventory management, order management, shipping management, returns management, and more.

In addition, some of the benefits of a warehouse management system are:

- It helps in optimizing the warehouse spaces by analyzing the floor plan based on the requirements and goods that need to be stored.

- It enables better visibility into the inventory, which further caters to reduced wastage alongside fulfilling the market demands accordingly.

- The automated processes ease complex tasks while saving time and money and reducing manual labor.

- It also helps in optimizing the supply chain processes thus improving the operational efficiencies alongside leveraging the capabilities of the existing resources.

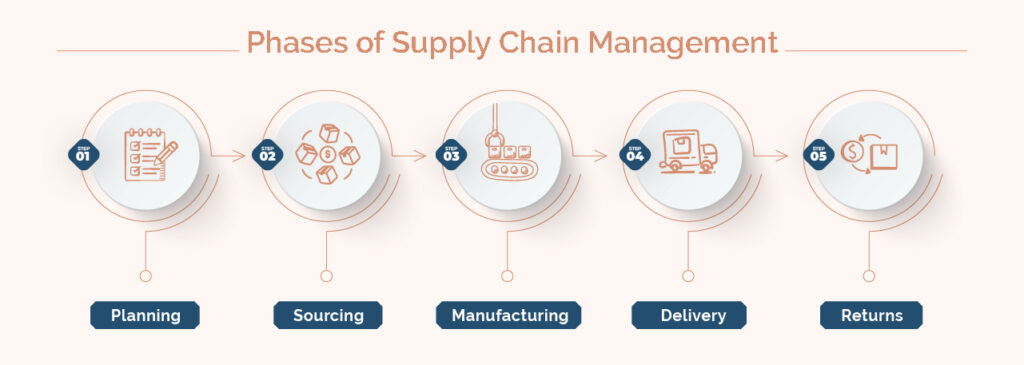

Stages of the Supply Chain Process

The supply chain process refers to transforming raw materials into finished goods and delivering them to the end customer.

It comprises a wide network of people, businesses, and service providers that work together. The key stages of the supply chain process are:

- Planning

- Sourcing

- Manufacturing

- Delivery

- Returns

Planning – This is the primary step in the supply chain management process. In this step, the needs and current market conditions are analyzed to determine the supply of the goods. Here the raw materials required to produce the goods are planned based on the quantity, staffing needs, equipment, and several other aspects.

Sourcing – In this step, the raw materials required for manufacturing goods and products are sourced from the vendor/supplier. It also ensures that the vendor has the flexibility to supply goods in an emergency while meeting the desired quality of raw materials.

Manufacturing – This is the core step of the supply chain process. In this step, the labor/staff uses the necessary tools and techniques to transform the raw materials into a finished product.

This stage can be divided into several other steps like testing, packaging, and more depending on the product type.

Delivery – Once the final product is packed and the sales strategy is finalized, the products must reach its customers. This step includes multiple methods of distribution through a robust system while keeping the product safe along with on-time delivery.

Returns – Also known as reverse logistics, this step aids with providing customer support alongside the return of goods. It ensures that the refund of exchange of the goods is made appropriately to deliver improved customer satisfaction while aiding you to gain the trust of the customers.

Now that you know the stages of the supply chain process, it is critical to know that the warehouse management system plays an important role in enhancing the supply chain efficiency.

Fulfillor’s warehouse management solution is one such system that helps streamline and boost the efficiency of the supply chain process.

How can a WMS enhance Supply Chain Management?

A warehouse management solution aids with several benefits to boost the efficiency of the supply chain process.

It helps in seamless workflows of the supply chain process, where the WMS helps the suppliers store goods alongside providing the location of the goods stored in the warehouse. This in turn helps reduce the efforts and also saves time, as the system serves you with the results as per your requirements.

It serves as a centralized platform that enables you to manage every activity and warehousing function from a unified platform. It helps maintain consistency in the business alongside making the processes quicker.

As we know inventory plays an important role in the warehouse. A WMS helps enhance the supply chain processes by providing real-time visibility of the stock levels with accurate statistics that further help predict the demand and supply of goods in the market.

A WMS further aids in automating the supply chain processes. It implies that the complex processes are simplified, thus reducing manual labor and errors, further leading to increased productivity. Thus, it helps in making the best use of the available human resources in the most efficient manner as per the business requirements.

In addition, a warehouse management system also helps you gain a competitive edge in the market. It analyzes real-time data and insights based on usage patterns, market trends, and consumer behavior which results in an improved decision-making process for your business. It also helps boost the profitability of your business.

FulFillor’s WMS to Boost Supply Chain Efficiency

The warehouse management system plays an important role in boosting the supply chain efficiency of a business. It caters to countless benefits alongside reducing costs and boosting revenue generation opportunities for a business.

With FulFillor’s WMS you can enhance the supply chain process and ensure enhanced productivity. Our solution is designed to streamline the supply chain management process while helping you leverage your business capabilities.

So, why not make the next move?

Reach out to us via e-mail or contact us, and we will help you with a solution that perfectly serves all your business needs.