Fulfillment Service Offerings

Pick, Pack, & Ship

Carton Bulk Fulfillment

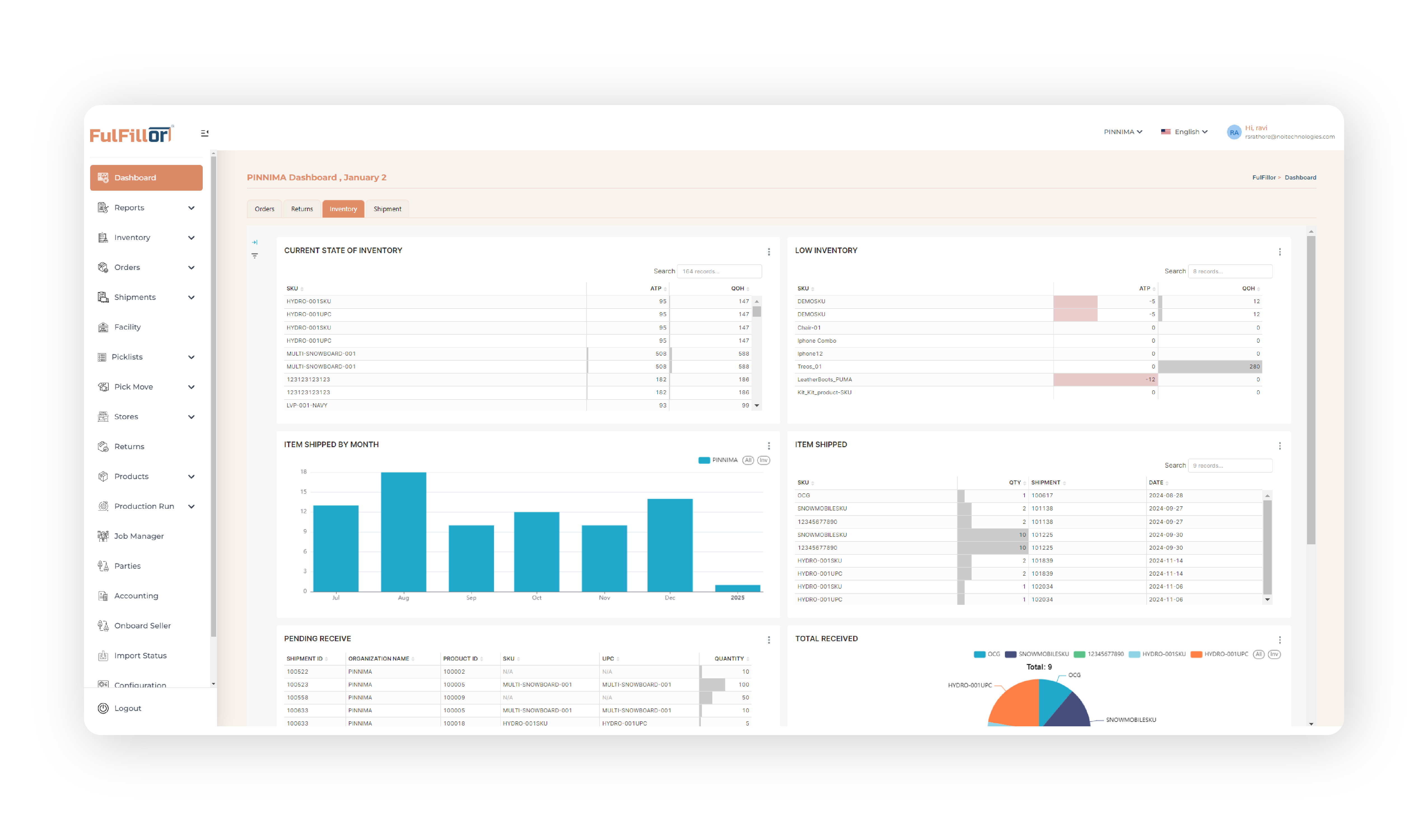

Inventory Management

Item Labeling

E-Commerce Fulfillment

Retail Fulfillment

Ready to Learn More About FulFillor’s WMS Solutions?

Our Solutions

How does Fulfillor, fulfill your requirements ?

our personal assistant at work is now tech-led! Let’s make your business accessible at a global level with Fulfillor! Our cost-effective solution offers features such as seamless order fulfillment, live tracking, smart inventory management, and hassle-free integrations—so your business can grow without limits.

Speak With Our Experts

Connect

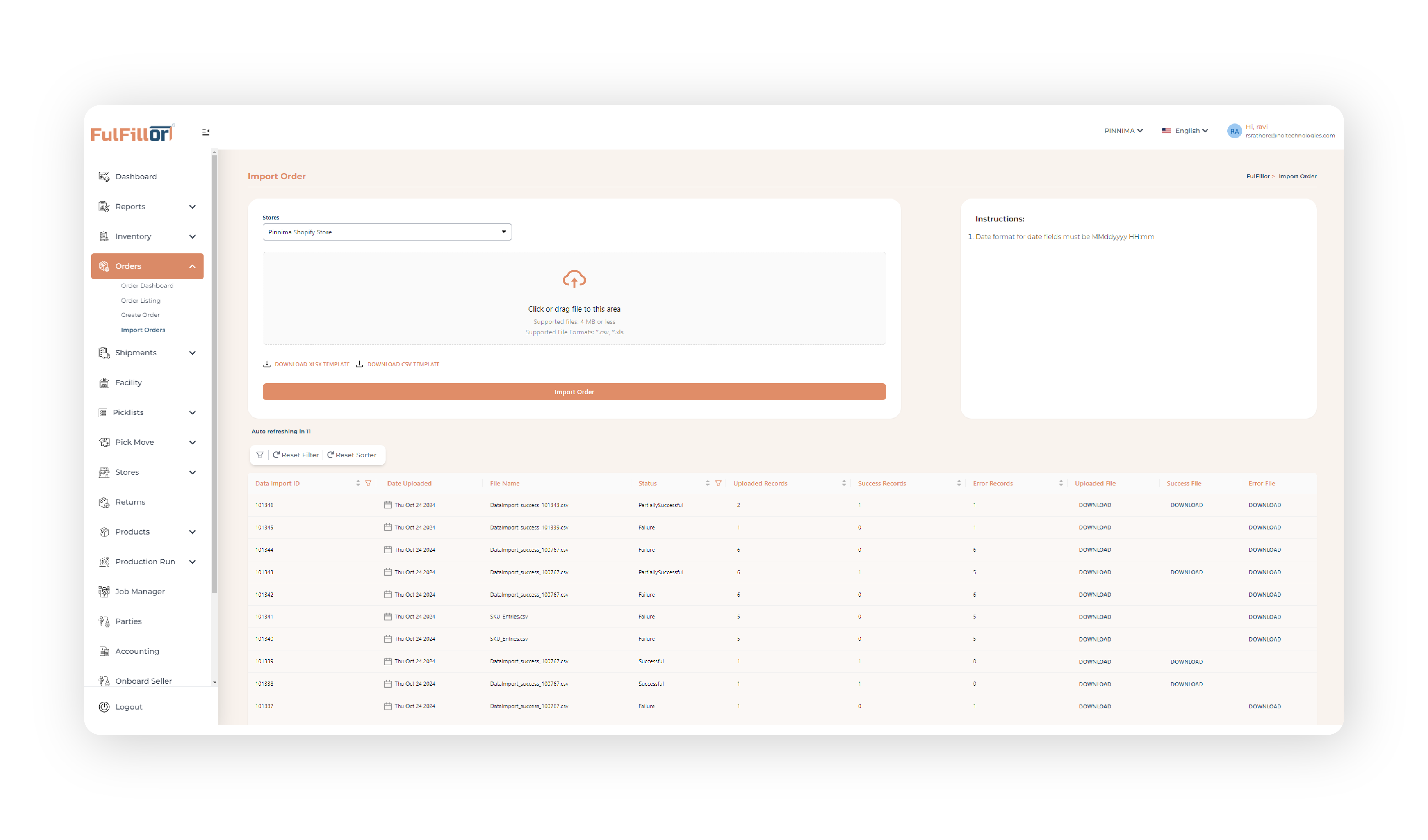

Sync and integrate your sales channels with our platform and you can remotely monitor and manage your business in real-time.

Store

Get a bird’s eye view and keep track of all your stock levels at the fulfillment center to ensure timely and cost-effective delivery.

Pack & Ship

We understand the importance of a satisfied customer and our services encourage quick and safe deliveries with careful packaging.

Track

Not just you, but even your customers can track the real-time location of their packages and shipments, ensuring transparency of services.

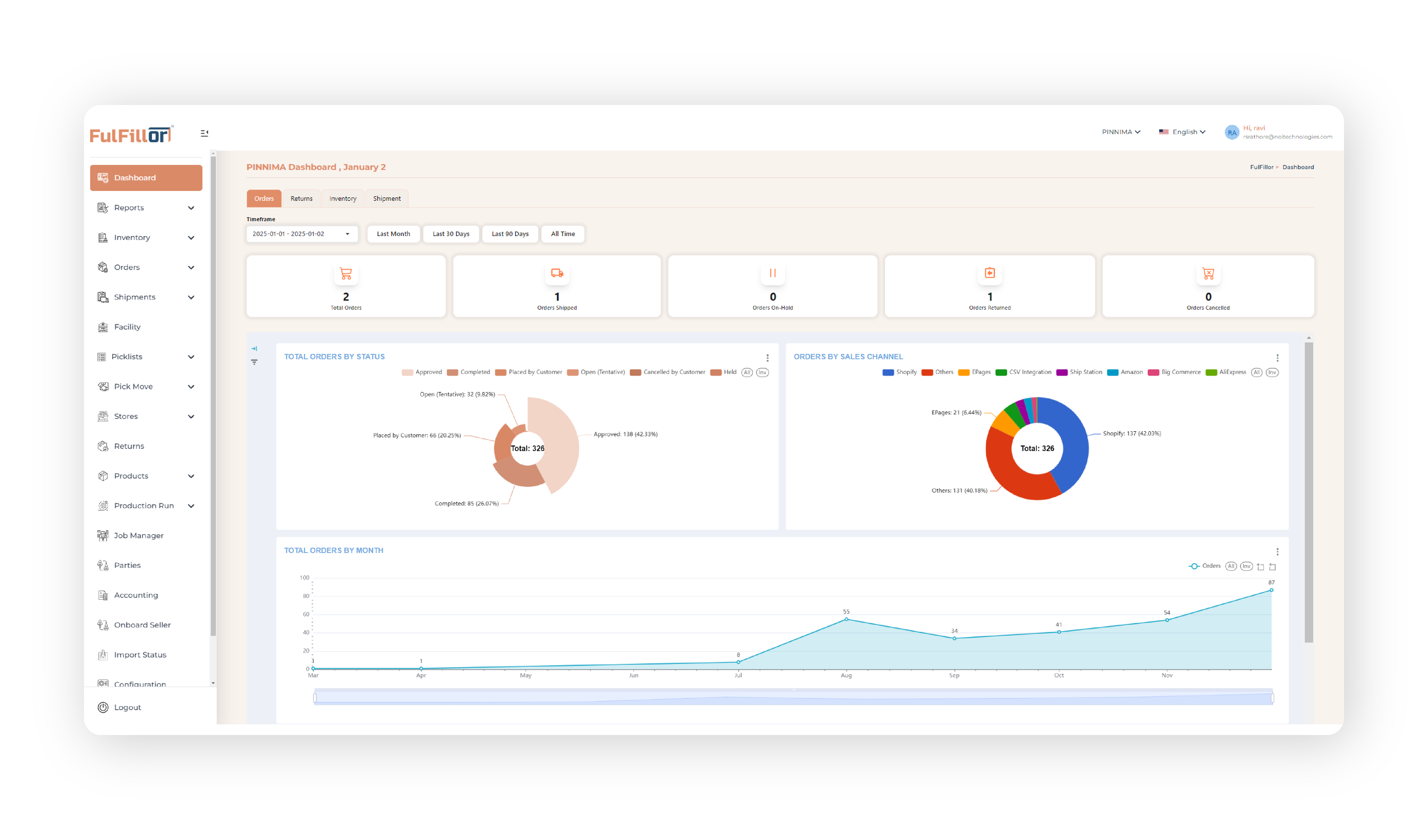

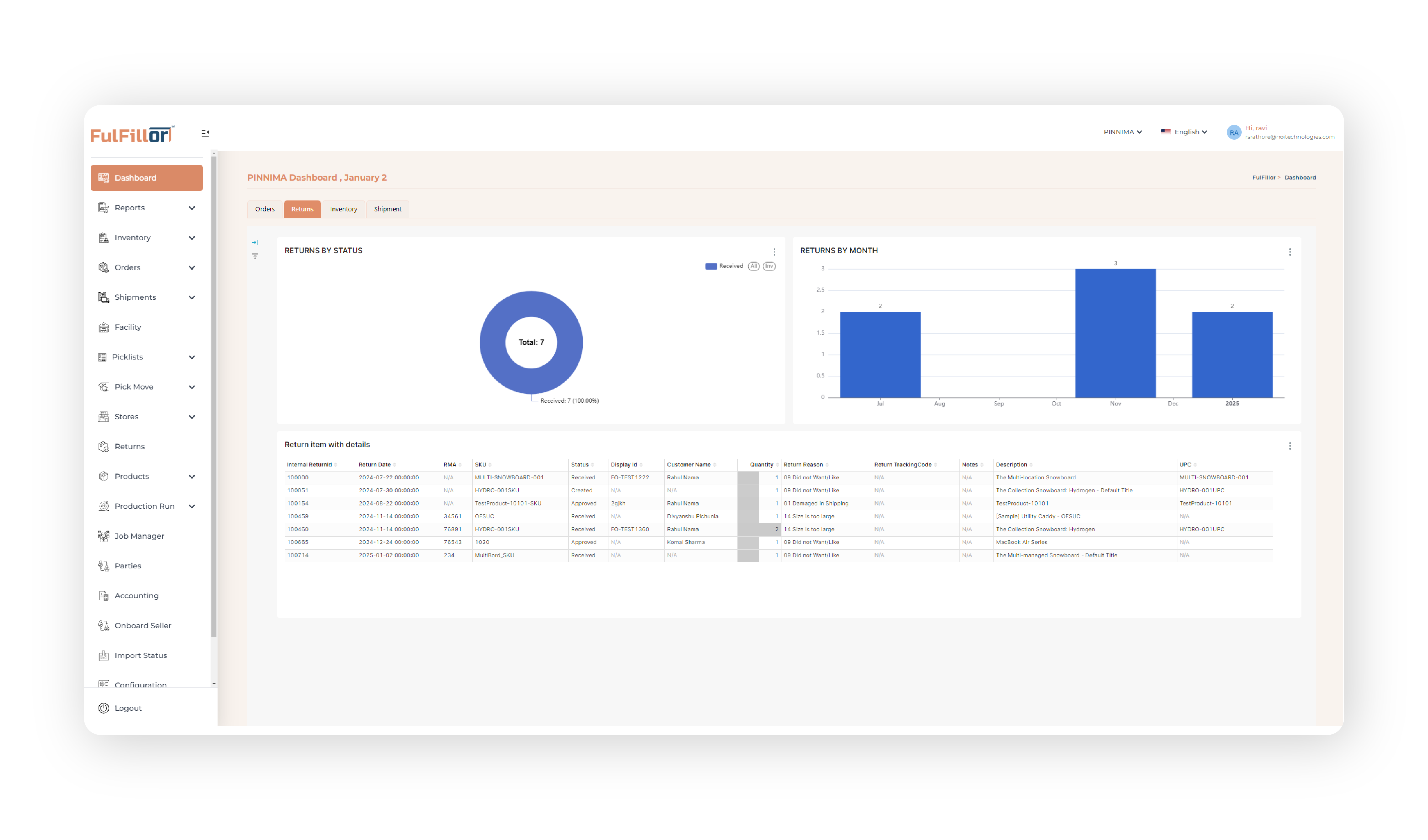

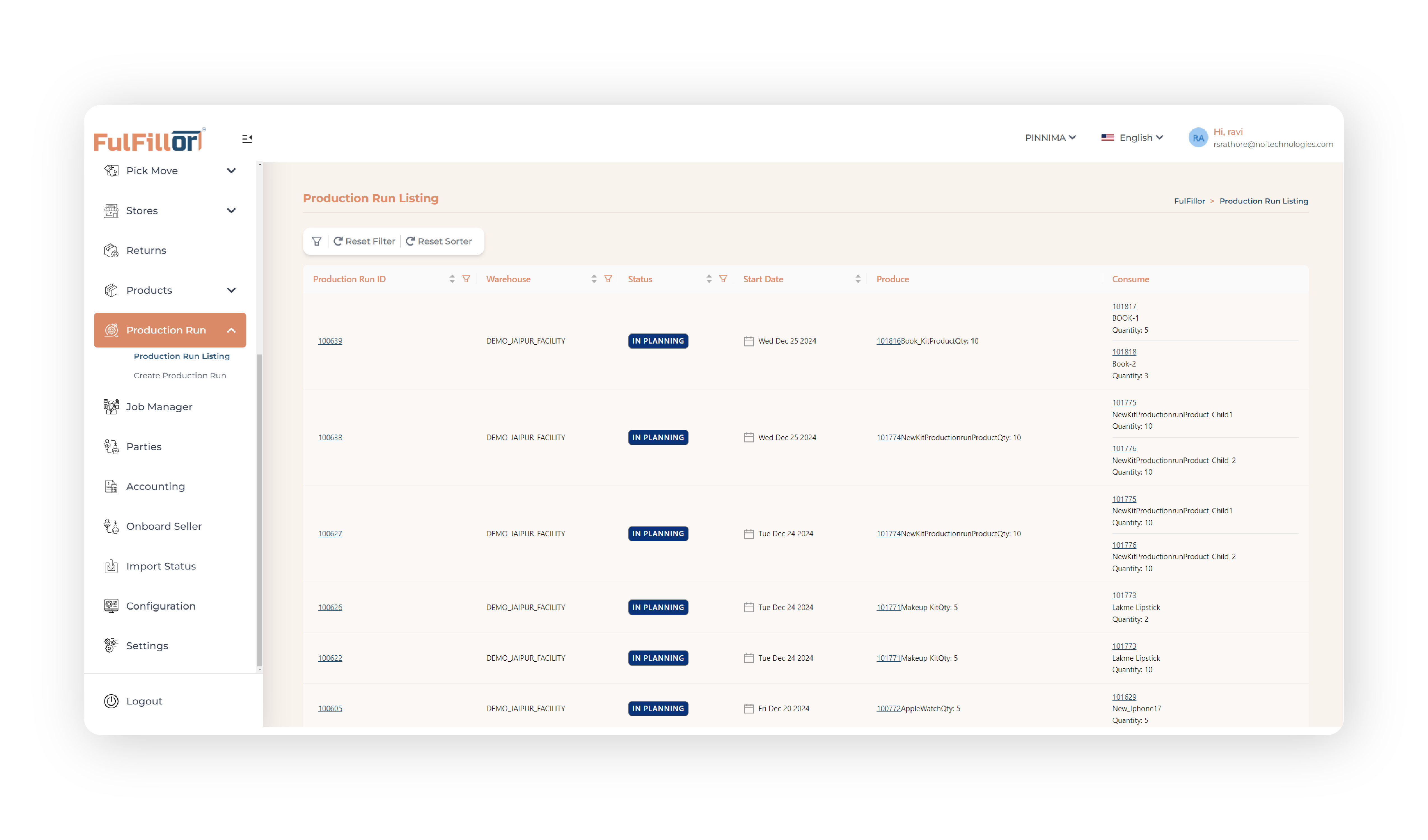

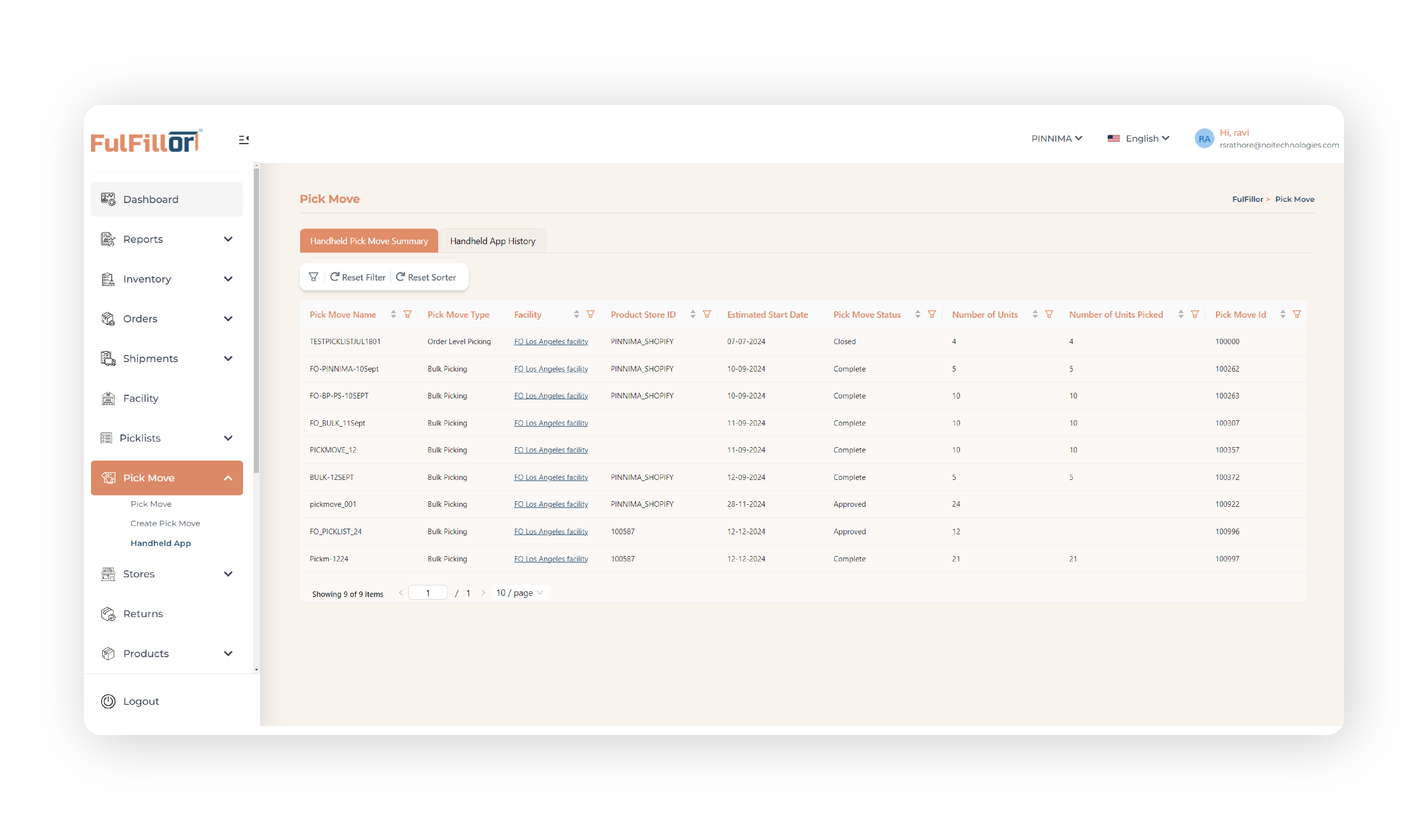

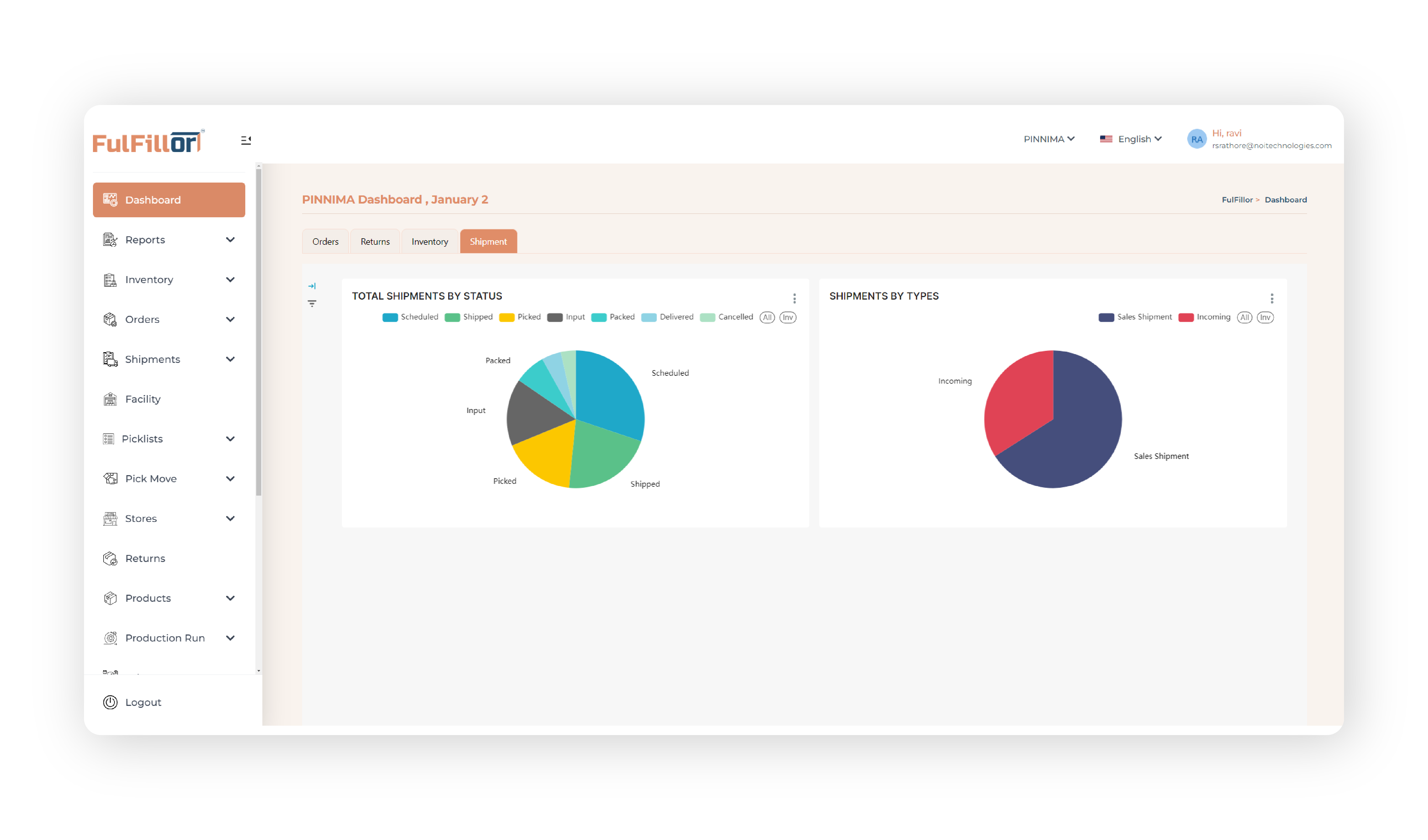

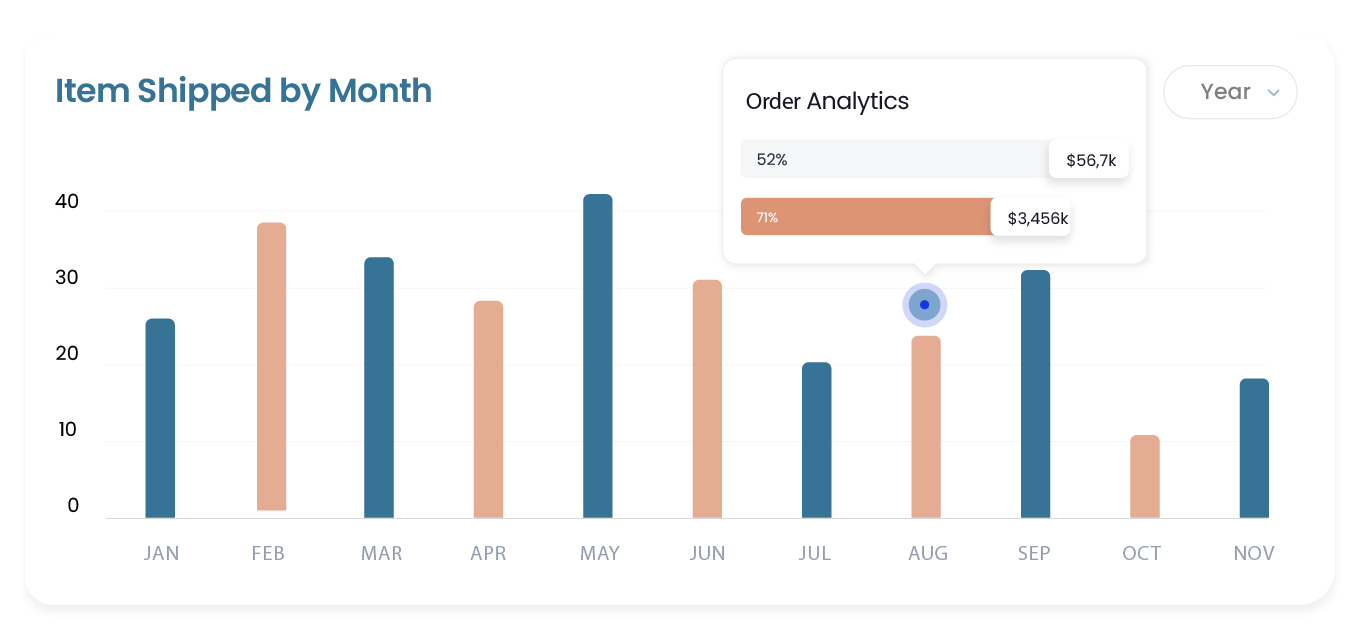

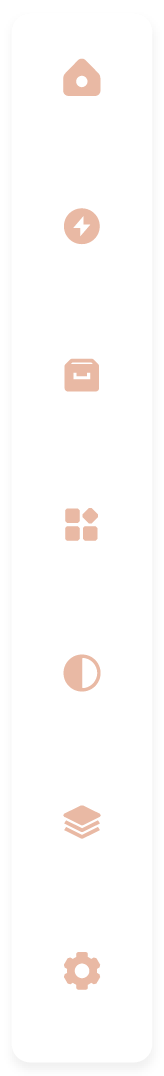

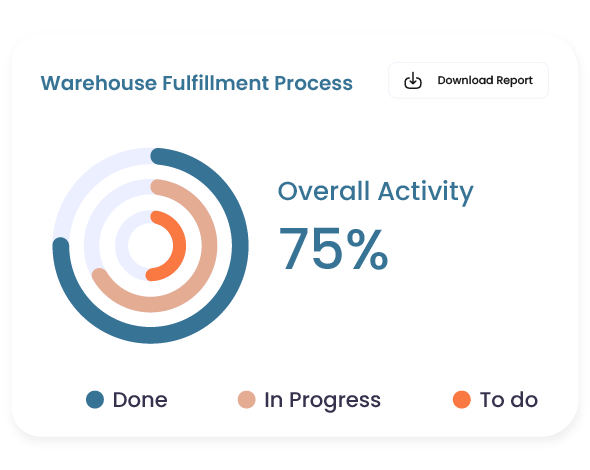

Streamline Operations and Monitor Progress in Real-Time

Have full supply chain oversight with our Warehouse Management System and 3PL Software – Fulfillor. Everything from live inventory updating and full-scale order monitoring and management is all set to help you ease up logistics and help your business soar high. Fortify your logistics operations with sophisticated analysis of your operations, process automation, and detailed custom recommendations.

Are you a business owner willing to bring about the change in your operations?

Book a Demo TodaySolutions by Industry

Over 150+ Integrations to Simplify Your Operations

View all our integrations- Shopping Carts

- Marketplaces

- Couriers

- Accounting Systems

Shopping Cart Integration

Organize and manage your orders from different platforms like Shopify, WooCommerce, and Squarespace all in one place with the shopping cart integration. Sync and manage your business with ease in a centralized platform alongside providing efficient services and the ultimate shopping experience to your customers.

Partner with the best order fulfillment solution and ensure superfast deliveries along with hassle-free payments.

Learn more about Shopping Cart IntegrationFulfillor - Your Centralized Cloud Solution for 3PL and Warehousing

See how Fulfillor empowers businesses to easily streamline their 3PL and warehousing operations.

Efficient. Scalable. Cloud-Based.

Get Started

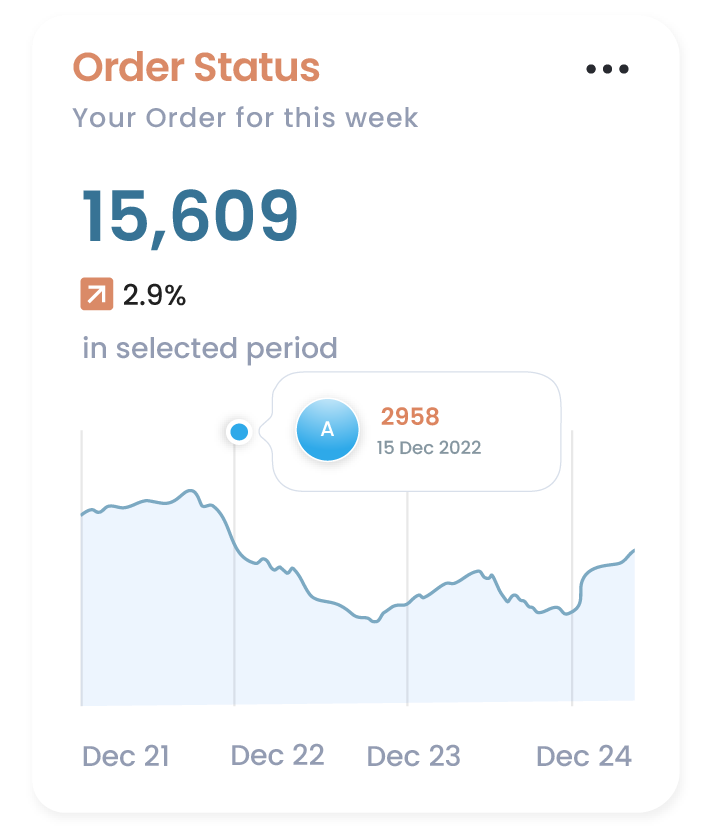

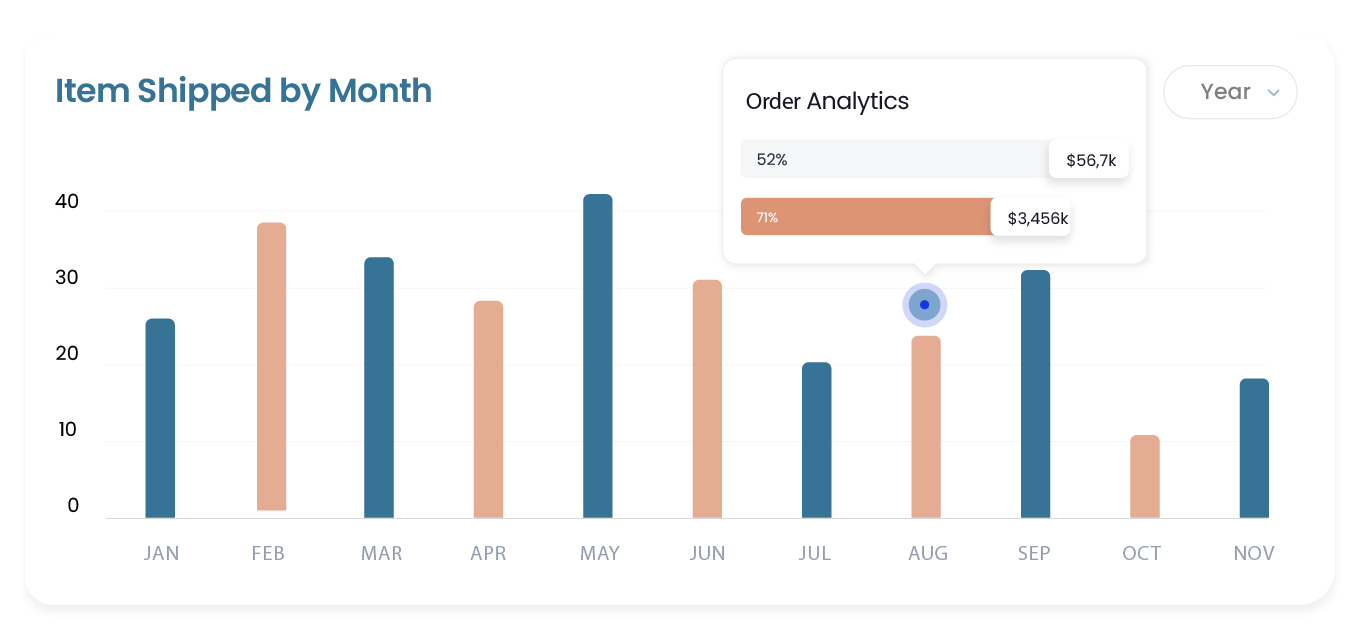

All Your Insights in One Place!

Manage, Monitor and Master with Fulfillor!

Unlock Your Business Potential with Fulfillor’s Seamless Integrations

Explore endless business opportunities with Fulfillor’s seamless marketplaces integrations and manage all your business operations with ease and efficiency all over the world.

In the digital age, connectivity is key. Fulfillor’s integration solutions bridge the gap between your various business systems, platforms, and applications. Experience the power of seamless data exchange, real-time updates, and a unified operational approach. Our integrations are designed to streamline your processes, enhance data accuracy, and save valuable time, allowing you to focus on growth and innovation.