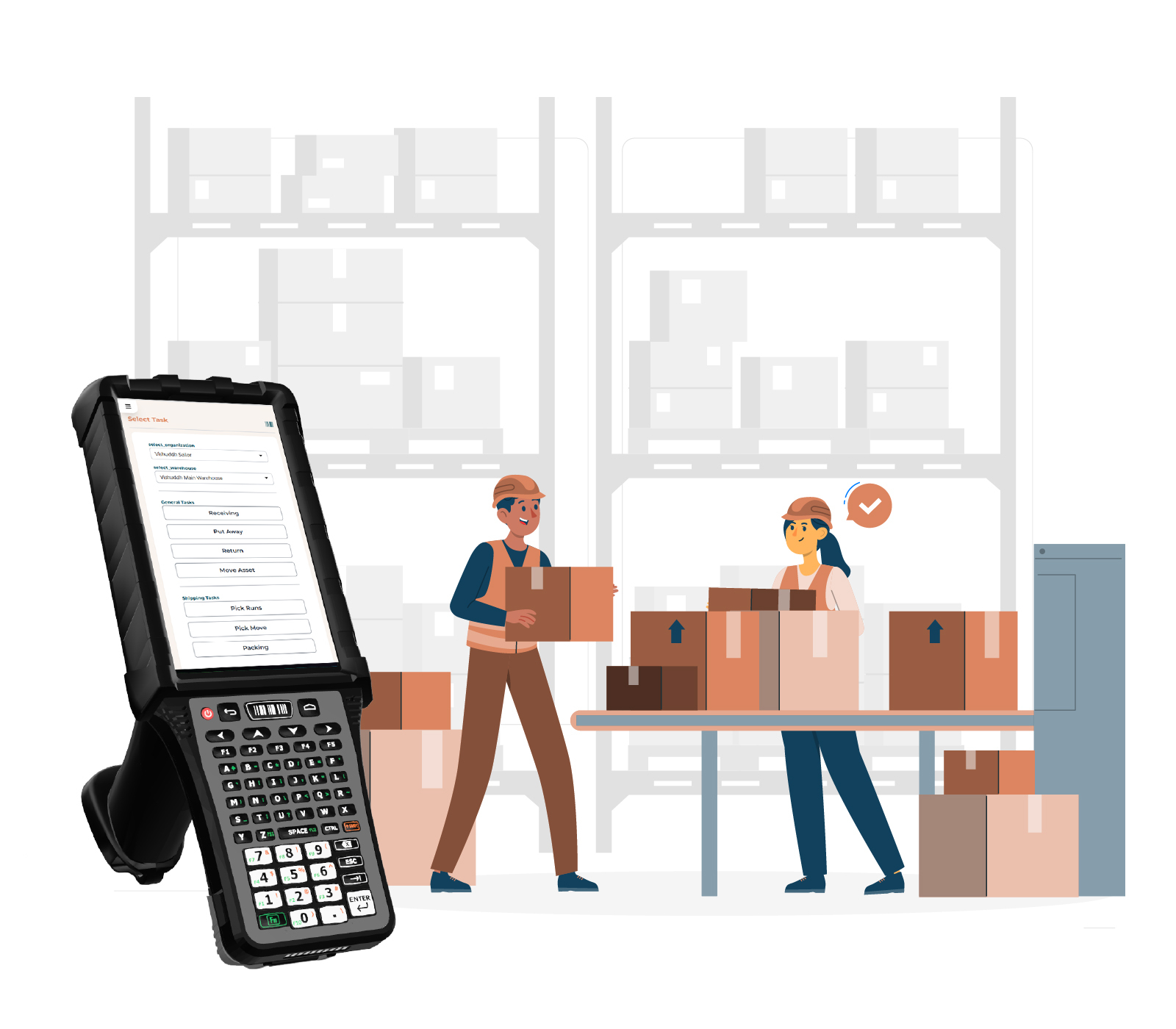

See Fulfillor’s pick, pack & ship software in action!

Key Features of Fulfillor - Smart Pick, Pack & Ship Software

Picking Paths Optimization

Fulfillor’s picking and packing system is designed to determine the most relevant picking paths, cutting down the time and distance your team has to cover inside the warehouse. By reducing unnecessary travel and wasted effort, it streamlines the picking, packing, and shipping process, reducing assumptions, errors, and wasted time. Without assumptions, errors, and wasting time, it guides your warehouse employees to pick items of your orders quickly and accurately.

The Perfect Pick, Pack & Ship Software

Fulfillor’s easy-to-use interface makes understanding our dynamic order fulfillment software so effortless. With real-time visibility and insights, picking path optimization, and batch picking, our software lets businesses boost their warehouse efficiency by showing up-to-date inventory, reducing picker travel time, and enabling multiple orders to be picked together efficiently.

Order Processing Choices

Fulfillor WMS supports multiple picking methods to fit your business model

Single Order Picking : best for small order volumes.

Batch Picking : pick items for multiple orders at once.

Zone Picking : assign workers to warehouse zones.

Wave Picking : group orders by carrier or shipping deadline.

This flexibility ensures faster, more accurate order processing and fewer customer returns.

Seamless Shipping Integrations

Fulfillor connects directly with carriers to generate labels, compare shipping rates, and update tracking in real time. This ensures every order moves from packing to shipping quickly, accurately, and at the best possible cost.

Ready to optimize your warehouse workflows? Book your personalized demo with Fulfillor.

Discover Frequently Asked Questions from Our Support

The picking and packing process involves locating items within the warehouse and intelligently packing them for shipment to customers, ensuring correct, efficient, and reliable dispatch.

Pick, pack, and ship is the process of selecting items from inventory, packing them securely, and shipping them to customers. It ensures fast, accurate, and efficient order fulfillment.

Picking and packing software helps simplify and enhance picking and packing activities, allowing warehouse staff to pick the items precisely and pack them effectively and efficiently.

With barcode scanning and real-time validation, updates have been sent to staff about incorrect items or wrong quantities.

Yes, Fulfillor’s pick and pack software is customizable, allowing companies to customize their picking and packing workflows, order processing methods, and inventory management functionality to fit their specific business needs.

Yes. Fulfillor’s 3PL WMS supports multiple clients, warehouses, and order types in one platform, ensuring seamless inventory visibility and efficient pick, pack, and ship workflows across sites.

Yes, it is designed to support multiple warehouse locations effortlessly. Businesses can handle inventory, picking, packing, and other processes across multiple sites simultaneously and efficiently. This supports brands with intricate logistical needs.