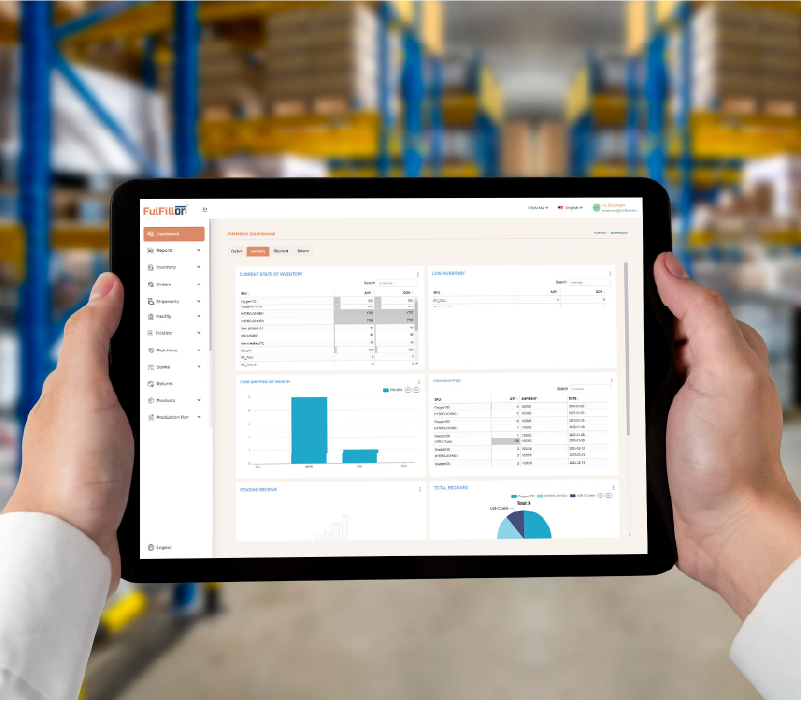

See How FulFillor Improves Warehouse Labor Performance

Warehouse Labor Management Features for 3PL and Warehouse Operations

Real-Time Warehouse Attendance and Labor Tracking

Track employee attendance and break times in real time to improve payroll accuracy, maintain compliance, and control labor costs. The LMS delivers precise workforce data to support smarter labor planning and scheduling.

Live Workforce Performance and Location Tracking

Monitor team performance and location in real time to improve warehouse productivity and workforce visibility. Track task-level activity, identify who is working on what, and optimize travel paths to increase operational efficiency.

Proactive Task Assignment and Labor Allocation

Plan and assign warehouse tasks in advance to reduce idle time and improve workforce productivity. The LMS enables balanced labor allocation, overtime control, and more efficient shift planning.

Real-Time Performance Alerts and Bottleneck Detection

Receive automated alerts when inactivity, delays, or workflow bottlenecks occur. The LMS helps managers take corrective action quickly, reduce inefficiencies, and prevent unnecessary labor costs.

Warehouse Labor Analytics and Performance Reportings

Generate detailed reports on labor performance, task efficiency, and completion rates to support data-driven decisions. The LMS provides visibility into warehouse KPIs, productivity trends, and incentive program performance.

Labor Cost Control and Overtime Management

Monitor labor hours, overtime trends, and workforce utilization in real time to prevent cost overruns and maintain operational efficiency. The LMS offers clear visibility into labor expenses, helping managers optimize staffing levels while meeting service targets.

Why FulFillor Is Built for Modern Warehouse Labor Management

FulFillor’s warehouse labor management system is designed for 3PLs and warehouse operators who need real-time workforce visibility, measurable productivity improvements, and tighter control over labor costs.

Streamlined Labor Planning and Workforce Control

A warehouse labor management system (LMS) streamlines labor planning, task assignment, and workflow coordination across 3PL and warehouse operations. By ensuring the right employees are assigned to the right tasks at the right time, the system improves productivity, strengthens accountability, and helps reduce overall labor costs.

Warehouse Labor Analytics and Performance Insights

Access real-time labor performance metrics and historical workforce trends to make informed operational decisions. The system gives you clear visibility into warehouse KPIs, productivity patterns, and cost drivers to support ongoing performance improvement. The LMS provides real-time visibility into warehouse KPIs and performance trends, supporting AI-powered labor optimization across warehouse operations.

Centralized Workforce Communication and Task Visibility

Enable real-time communication, task updates, and schedule visibility within a centralized warehouse labor management system. Clear access to performance feedback and operational updates helps teams stay aligned, reduce miscommunication, and improve execution on the warehouse floor.

Reduce Labor Costs and Overtime

A warehouse labor management system (LMS) helps reduce unnecessary labor expenses by improving workforce visibility and optimizing task allocation. By identifying inefficiencies, controlling overtime, and automating manual processes, it increases productivity while lowering operational costs. It also supports planning ahead and automating warehouse labor shortages, helping operations maintain performance even when staffing is tight.

Integrations with WMS, ERP, HR, and Payroll Systems

The warehouse labor management system integrates with existing platforms, including Warehouse Management System (WMS), Enterprise Resource Planning (ERP) software, Manufacturing Execution Systems (MES), HR, and payroll tools. These integrations create a connected data environment that provides real-time visibility into labor tracking, productivity metrics, and workforce performance while reducing data silos across warehouse operations.

Improve Workforce Visibility and Control Labor Costs Across Your 3PL Operations

Frequently Asked Questions About Warehouse Labor Management Systems

Warehouse labor management software is a system that helps warehouses and 3PL providers monitor employee productivity, track attendance, manage labor costs, and measure workforce performance. It provides real-time visibility into task completion, shift efficiency, and operational KPIs. By centralizing workforce data, the system improves labor planning and overall warehouse efficiency.

A warehouse labor management system (LMS) improves productivity by providing real-time visibility into employee performance, task progress, and workflow efficiency. Managers can identify bottlenecks, reduce idle time, and allocate labor more effectively. Data-driven insights support better scheduling, faster execution, and measurable performance improvement across warehouse operations.

Yes, a warehouse labor management system (LMS) helps reduce labor costs and overtime by improving workforce visibility and optimizing task allocation. Real-time tracking identifies inefficiencies, excess idle time, and overtime trends. By enabling better scheduling and workload balancing, the system lowers unnecessary labor expenses while maintaining service performance.